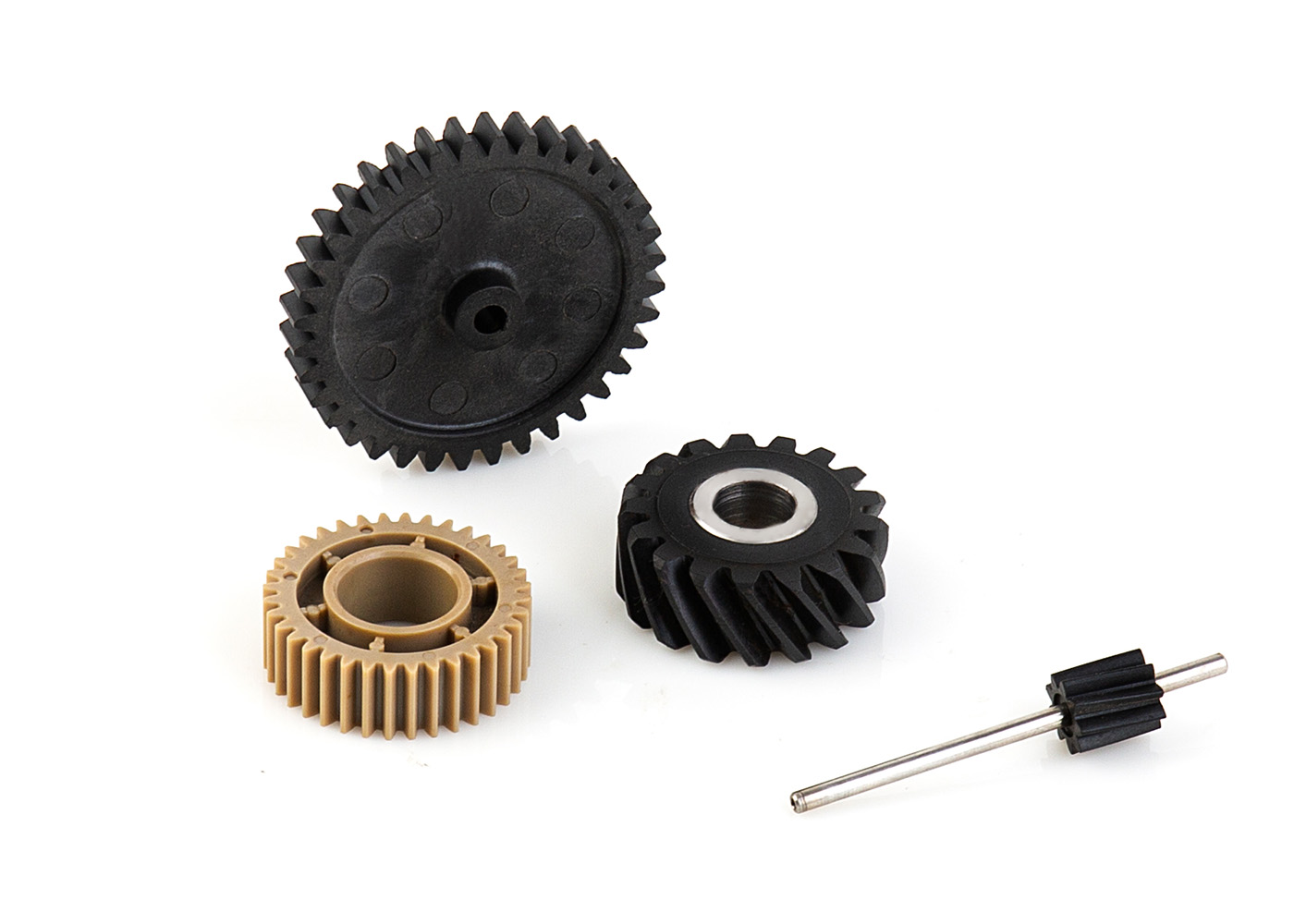

We are a Chinese enterprise founded in 2007. we forgot to come up with one! Our team is a dedicated fusion of professional production and R&D experts, We have an equally excellent sales team as well.We are truly delighted that you have found your way here and have the opportunity to get to know us. We are passionate about the world and its future. Our vision is to see our products not only used by more enterprises but also to have them spread across all corners of the globe. We are confident that this is a common aspiration for you as well. Let's work together and make this vision a reality!

+86 519 83903275

info@ybpeek.com